When heads of state, global business leaders and other high profile people visit Indonesia, they often prefer to stay at hotels that are not merely renowned for its luxury and beauty but also for its food safety standards. ‘An ounce of prevention is worth a pound of cure‘ is nowhere truer than in food safety and hygiene. Effective food safety systems in hotels are needed to manage and ensure the safety and suitability of foodstuffs.

Hotels are complex systems, with thousands of semi-raw materials, ingredients, people and processes and a continuous need for training and testing. It is a challenge to implement these practices and get certified according to the HACCP (Hazard Analysis & Critical Control Points) food safety standards. This is the internationally recognized methodology that helps companies in the food and beverage industry to identify their food safety risks, prevent food safety hazards and address legal compliance.

Hotels are complex systems, with thousands of semi-raw materials, ingredients, people and processes and a continuous need for training and testing. It is a challenge to implement these practices and get certified according to the HACCP (Hazard Analysis & Critical Control Points) food safety standards. This is the internationally recognized methodology that helps companies in the food and beverage industry to identify their food safety risks, prevent food safety hazards and address legal compliance.

Hotel chains necessarily make huge investments in food safety in their endeavor to delight guests not only in terms of enjoying great food and service but also peace of mind knowing that rigorous standards of hygiene and safety are in place. Attaining HACCP Certification demonstrates an ongoing commitment to providing the safety, control and management of healthy and quality food in accordance with worldwide hotel industry expectations. The process is a systematic preventive approach to food safety which encompasses physical, chemical, and biological hazards identification and rectification from receiving, storing to preparation and serving food.

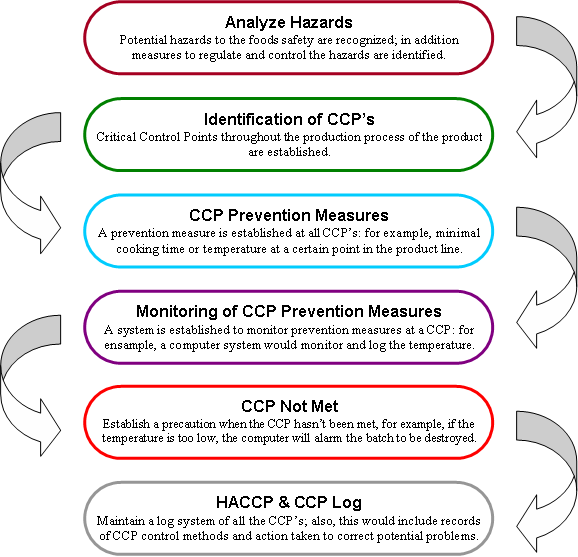

HACCP certification is a food safety system that is one of the most sought-after accreditation in the hospitality and food industries. It focuses on preventing hazards that could cause food-borne illnesses by applying science-based controls, from raw material to finished product. The methodology is based on 7 key principles: hazard analysis, critical control points identification, establishing critical limits, monitoring procedures, procedures and record-keeping and documentation

Critical control points are managed by appropriately trained in-house staff, providing for a truly hands-on quality management system at each and every operation as HACCP is a process of continuous improvement in the entire food production process, covering persons, the work environment, and food products. A food safety program however does not just stop with HACCP. To be effective, sub-systems such as pest control, recall protocols, hygiene and sanitation need to be developed and implemented. Additionally suppliers and distributors requirement to be ‘safe’ are also addressed through development of ingredient specifications and a vendor quality assurance system.

The Hazard Analysis Critical Control Point (HACCP) system is a scientific and systematic approach that identifies specific hazards and measures for their control to ensure the safety of food, as adopted by the World Health Organization, the US Food and Drug Administration, and many other agencies worldwide. Initially developed by the researchers and suppliers to the NASA space programme to provide astronauts with foods of the highest level of quality, HACCP is an effective tool to manage food safety. The application of HACCP in Indonesia refers to Indonesian National Standard (SNI) 01-4852-1998. Its application in the food industry has expanded to most parts of the world, and in Indonesia it has developed rapidly in the past decade for the preparation of safe foods at all levels: home, restaurant, and the hotel industry.

Consistent application of HACCP also a creates a superior working culture in which employees work better, cleaner, healthier and with greater discipline in line with the working guidelines, by maintaining personal cleanliness, cleanliness of equipment, and cleanliness of the work environment. At the same time hotel operators increase their competitive advantage and boost profit margins by delivering a superior standard of service.

As published in The Jakarta Post Wednesday, 10th Aug 2011